Features

- Easy Decontamination

- Survives Dry Pumping, Dirty Air and Sand

- Saves Time and Costs

- Part of Simple System

Datasheet

Double Valve Pump

Applications

Low Flow Sampling

Gives excellent VOC retention, comparable with bladder pump results. When using the Solinst Model 464 Electronic Pump Controller, the Double Valve Pump (DVP) can be adjusted to provide a continuous output of 100 ml/min or less.

Non-Vertical Applications

Operates effectively at almost any angle and can be placed under landfills, tailings, storage tanks or plumes.

Leachate/Product Pumping

Pneumatic drive pumps may be used for pumping contaminant liquids. High solids content, solvents, hydrocarbons, and other chemicals are easily and economically pumped.

Dedicated and Portable Systems

For long term monitoring it is best to dedicate the Double Valve Pumps to reduce sampling time and avoid cross-contamination. Dedicated well caps are designed for ease of use. Caps easily slip onto 2" or 4" wells, and have quick-connect fittings for the drive tubing and easy push-fit connections for the sample tubing.

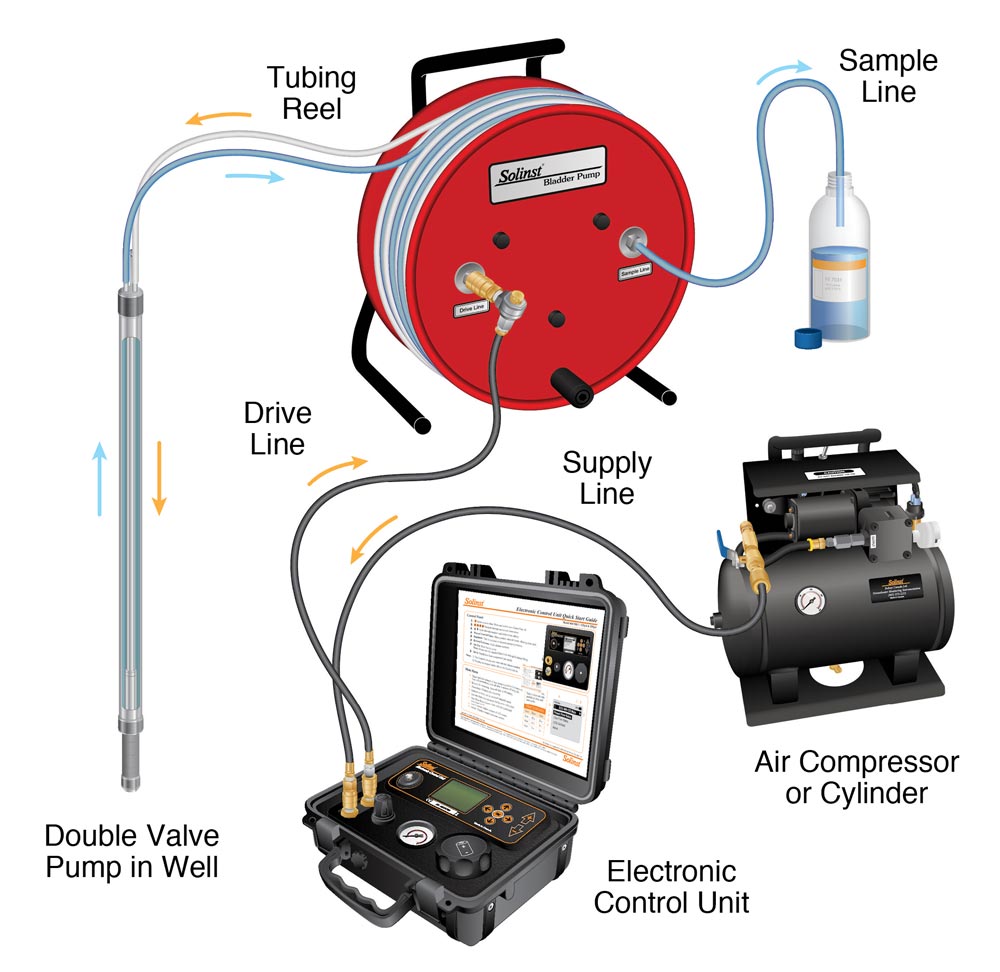

For less frequent sampling, reel mounted portable systems allow access to multiple monitoring wells, even in remote locations. The reel mounted portable units are free-standing with a convenient carrying handle. They can be made for almost any size or depth of application.

Operation

Double Valve Pump Operation

When the Double Valve Pump is placed in a well or borehole, water rises inside the pump and the tubing to static level. Gas supplied from the Controller pushes down on the water column contained in the drive line tubing, closing the check valve at the base of the pump. This forces water up the sample line tubing.

A vent period, during which the gas is released, allows hydrostatic pressure to refill the pump and drive line with sample water. The top check valve prevents water in the sample line from falling back into the pump body. This pressurization and vent cycle is repeated to bring water to the surface.

For proper collection of volatiles, the pressure applied must never be high enough, nor the drive period long enough, to enable gas to enter the body of the pump and aerate the sample. If operated properly, “air” will never come in contact with the sample water, which produces high quality VOC samples comparable to those of a bladder pump.

Flow rates vary with depth of pump below surface, depth below water level, size of drive and sample tubing, drive and vent cycle times, gas pressure applied, aquifer recharge, and size of pump body.

Electronic Pump Controller and Accessories

Electronic Pump Controllers

Solinst offers the Model 464 Electronic Pump Control Unit in both 125 psi and 250 psi versions. Both units use 4 AA batteries and are fully automatic with preset sample modes from high to low flow. This allows faster purge rates and precise low flow control to ensure a representative sample at 100 ml/min or less when sampling for VOCs.

The 464 Electronic Pump Control Unit can also be operated manually if your batteries run out in the field, using only a compressed gas source. In addition, up to 99 user-created flow rates can be saved in its memory.

The Control Units are supplied in a convenient rugged box, suitable for all environments. Quick-connect fittings allow easy, instant attachment to dedicated well caps or portable reel units, and to an air compressor or compressed gas source.

Sizes and Materials

Solinst offers Double Valve Pumps in 316 stainless steel with o-rings. The two standard pump body sizes are:

- 5/8" dia. x 1 ft long (16 mm x 305 mm)

- 1.66" dia. x 2 ft long (42 mm x 610 mm)

The Micro Double Valve Pump is a flexible, 3/8” (10 mm) diameter, PTFE Pump. It is ideal for low flow sampling in narrow applications.

Contact Us