- Representative water samples to submerged depths of up to 1200 m (4000 ft)

- No compressor needed, use a simple bike pump

- Ideal for deep water sampling of boreholes, wells, lakes, and oceans

- Perfect for applications similar to deep abandoned mine shaft monitoring

- Simple to use and to decontaminate

Datasheet

425 & 425-D Discrete Interval Samplers

The Solinst Model 425 Discrete Interval Sampler (DIS) is a stainless steel sampler, with LDPE tubing mounted on a convenient Solinst reel.

The reel has a pressure attachment for a high pressure hand pump, and a pressure/vent switch which is used to apply and release the pressure on the sampler. A sample release device is included with each standard Discrete Interval Sampler.

Solinst also offers the Model 425-D Deep Sampling Discrete Interval Sampler for obtaining samples from submerged depths as much as 1200 m (4000 ft).

Discrete Interval No-Purge Sampling

Discrete interval sampling is ideal for obtaining truly representative water samples and for obtaining samples of product (LNAPL and DNAPL). The DIS is ideal for groundwater sampling from below an oil/product layer on the surface of the water, as it allows a sample to be obtained which is untouched by the oil.

Discrete Interval Sampling is also used to profile open bodies of water, open boreholes and screened wells, and to collect samples from distinct levels or points of inflow. Mixing of water from different levels in the well is minimized.

The Model 425 Discrete Interval Samplers are also recognized as a no-purge sampler. No-purge, also known as zero-purge or passive sampling methods, have gained acceptance by many regulatory agencies worldwide for obtaining high quality groundwater samples.

These sampling methods are based on the principle that groundwater which flows into a well, maintains equilibrium with the adjacent water bearing unit. Sampling at the discrete interval should result in representative samples, without the need for purging.

425-D Deep Sampling Discrete Interval Sampler and Weight

Advantages

- High quality samples

- Sample has not been pumped through tubing

- No mixing of water from different levels

- Minimal disturbance of the water

- Easy disassembly for decontamination

- Avoids purging and disposal of purge water

- Less cost and time to retrieve samples

- Easy operation and transportation

Applications

- Obtaining a representative groundwater sample from below oil/product layers

- Discrete interval sampling in lakes, rivers and wells

- Chemical profiling of wells

- Sampling at points of inflow to well

- LNAPL and DNAPL sampling

Operation

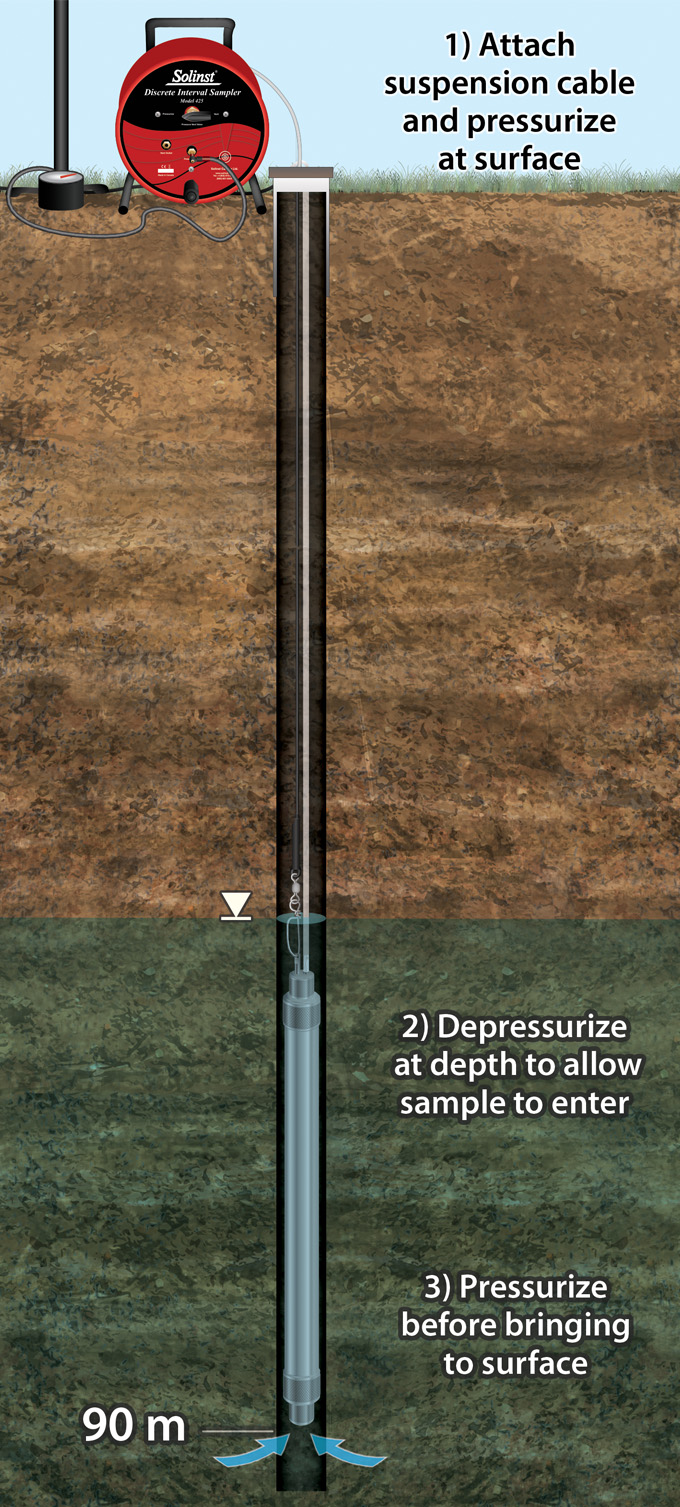

Standard Discrete Interval Sampler Operation

The Discrete Interval Sampler is pressurized before being lowered into the well to prevent water flowing into the sampler. Once the desired depth is reached, the pressure is released and hydrostatic pressure fills the sampler with water directly from the sampling zone. A floating check ball inside the samplers prevents water from entering the tubing, thus avoiding the need to decontaminate the interior of the tubing.

When the sampler is filled, it can be repressurized and raised to the surface. The sample is decanted using the sample release device, which regulates flow and minimizes degassing of the sample. The sampler is easily disassembled for decontamination.

| Recommended Operating Pressure | |||

|---|---|---|---|

| Submerged Depth (feet) | Pressure (psi) | Submerged Depth (meters) | Pressure (kPa) |

| 25 | 20 | 8 | 148 |

| 50 | 30 | 15 | 217 |

| 100 | 50 | 30 | 364 |

| 200 | 95 | 60 | 660 |

| 300 | 140 | 90 | 952 |

| Operating Pressure = (Submerged Depth in feet x 0.43) + 10 psi (Submerged Depth in meters x 9.8) + 70 kPa | |||

| Discrete Interval Sampler Capacity | |||

|---|---|---|---|

| English Units | Metric Units | ||

| Size | Capacity | Size | Capacity |

| 1" x 2' | 6 oz | 25.4 mm x 610 mm | 190 ml |

| 1.66" x 2' | 18 oz | 42 mm x 610 mm | 475 ml |

| 2" x 2' | 27 oz | 50.8 mm x 610 mm | 800 ml |

| 1" x 4' | 12 oz | 25.4 mm x 1220 mm | 365 ml |

| 1.66" x 4' | 32 oz | 42 mm x 1220 mm | 1000 ml |

| 2" x 4' | 61 oz | 50.8 mm x 1220 mm | 1800 ml |

| Other diameters and lengths available, on request. | |||

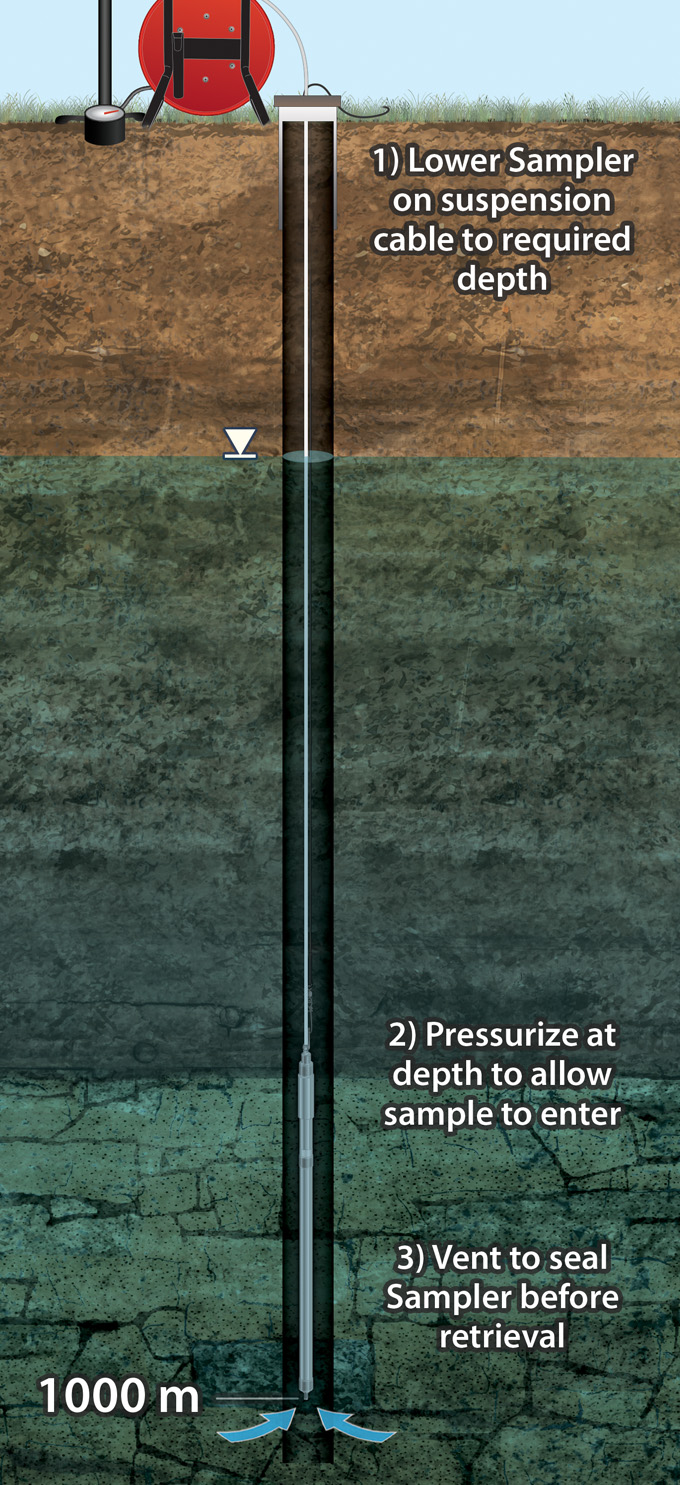

Deep Sampling DIS Operating Principles

To overcome buoyancy, weights are connected to the top of the Deep Sampling Discrete Interval Sampler before lowering. After the first 100 m (300 ft), one 2 kg weight is added for every additional 100 m (300 ft) of submerged depth.

Once the sampler reaches the desired sampling depth, it is pressurized. Using the basic principles of hydraulics, the pressure acts on the top of a piston (larger surface area) inside the sampler, overcoming the hydrostatic pressure acting on the bottom of the piston (smaller surface area) to allow sample water to enter.

As sample water fills the sampler, air from the sampler is vented through holes (covered with a Vyon filter) on the side of the sampler, which are also opened with the applied pressure.

After the sample is collected, the pressure is released, allowing the piston to reseal at the bottom of the sampler. The sealed sampler is then retrieved to surface, maintaining chemical stability of the sample.

At surface, the sample is collected by reapplying pressure to the Discrete Interval Sampler. The flow of the sample is regulated by the amount of pressure applied. The sampler is easily disassembled for decontamination.

| Recommended Operating Pressure and Weights | ||||

|---|---|---|---|---|

| Submerged Depth (feet) | Pressure (psi) | Submerged Depth (meters) | Pressure (kPa) | Number of Weights |

| 160 | 50 | 50 | 345 | 0 |

| 320 | 50 | 100 | 345 | 0 |

| 640 | 50 | 200 | 345 | 1 |

| 960 | 75 | 300 | 520 | 2 |

| 1280 | 100 | 400 | 690 | 3 |

| 1600 | 125 | 500 | 860 | 4 |

| 1920 | 150 | 600 | 1030 | 5 |

| 2250 | 175 | 700 | 1200 | 6 |

| 3250 | 200 | 1000 | 1380 | 9 |

Contact Us