Laser Marked Flat Tape Interface Meter

- Durable and easy to decontaminate

- Narrow 16 mm (5/8") diameter probe

- Sturdy free-standing reel with carrying handle

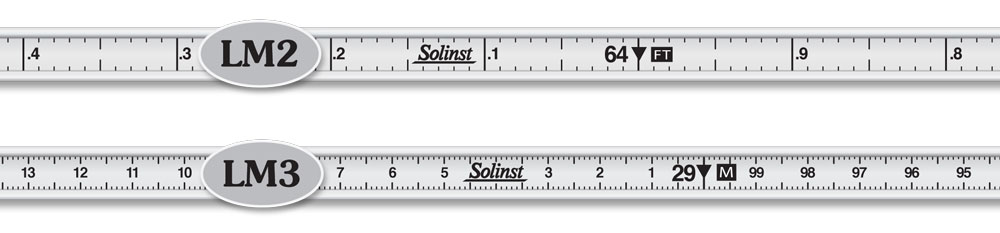

- Accurately laser marked each mm or every 1/100 ft

- Lengths to 300 m or 1000 ft

- Markings certified traceable to national standards

- CSA certified intrinsically safe for hazardous locations

- CE Standards & ATEX certified

Solinst Oil/Water Interface Meters give clear and accurate measurements of product level and thickness in wells and tanks.

Determination of both light (floating) non-aqueous phase liquids (LNAPL) and dense (sinking) non-aqueous phase liquids (DNAPL) is quick and easy. The factory-sealed probe is pressure proof (up to 500 psi) and tapes are available in a range of lengths from 30 – 300 m (100 – 1000 ft).

The 16 mm (5/8") diameter probe allows easy access through tight spaces and into narrow wells. The probe is designed for use in various monitoring applications.

Hazardous Locations Use

Model 122 Interface Meters have been approved for use in explosive environments. They are suitable for use in hazardous locations Class I, Div 1, Groups C&D based on standards of the Canadian Standards Association (CSA).

The Model 122 Interface Meter with laser marked tape is now ATEX certified under directive 94/9/EC, as II 3 G Ex ic IIB T4 Gc.

The grounding strap is a safety essential when the meter is used in potentially explosive environments. It also ensures that the electronics are properly protected.

Accurate, Reliable, Robust

- Designed for rugged field use

- Stable electronics with automatic circulatory testing

- Laser marked flat tape is easy to decontaminate; resists stains

- Tape uses stranded stainless steel and copper coated steel conductors:

- high in tensile strength; electrical efficiency

- non-stretch; does not corrode

- Sturdy free-standing reel with carrying handle

High Quality Design

The state-of-the-art electronics include automatic circuitry testing when the ‘On’ button is used; 120 hours of on-time battery life; clear signals; and high accuracy. The circuits are powered by a single standard 9V battery which is housed in an easy-access drawer in the faceplate of the reel.

Infra-red refraction is used to detect liquids and conductivity to distinguish water. Both optical and electronic sensors are precisely aligned at the same zero point. The factory sealed probe does not need to be accessed by the user. An integral stainless steel shield protects the sensors. It is set permanently into place, yet allows for easy cleaning.